When it comes to high-performance alloys Inconel and Hastelloy are two of the most widely used materials. Both are known for their excellent corrosion, heat and pressure resistance making them suitable for application in industries such as aerospace, chemical processing and oil and industries. These two have unique characteristics and uses. This blog will explain the difference and the type of Inconel and Hastelloy that are available for you to make the right choice.

What is Stainless Inconel?

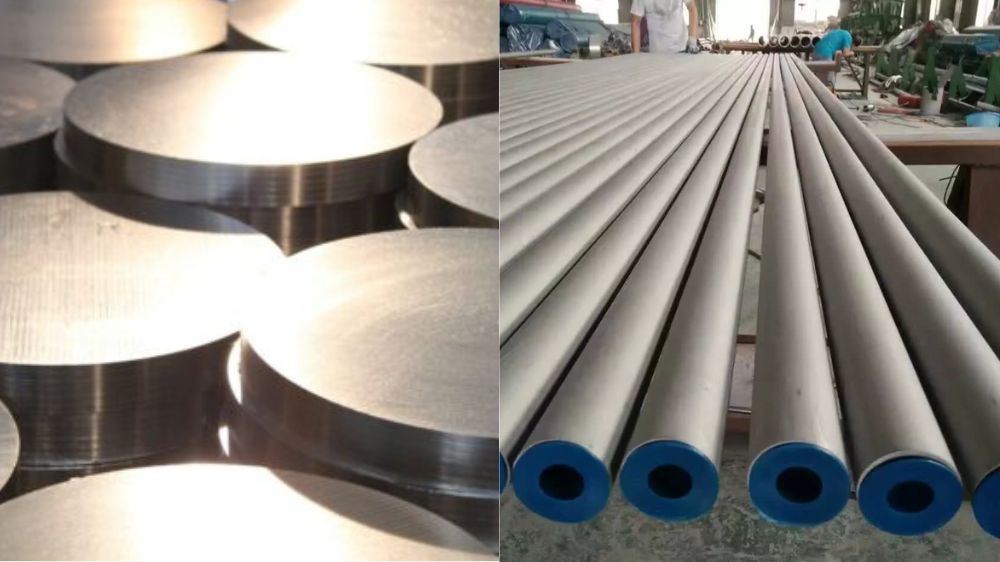

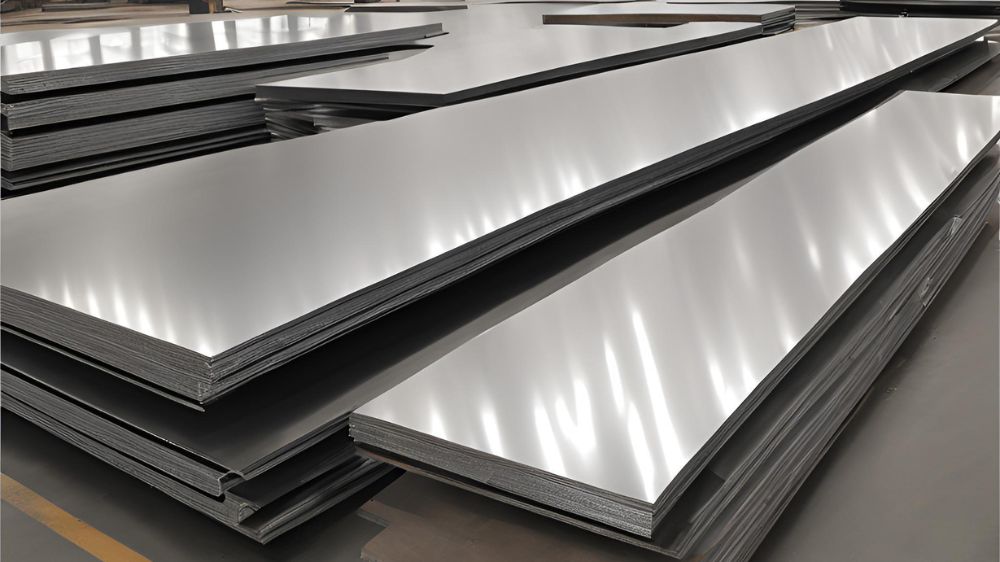

Inconel is made of nickel-chromium-based superalloys that provide high strength and high resistance to various severe conditions. These alloys are able to withstand high temperatures and pressures and are therefore used in jet engines, gas turbines and nuclear reactors. Inconel 600 Sheets, Inconel 600 Coils and Inconel 600 Plates are popular forms of this alloy widely used in industries requiring durability and reliability.

Types of Inconel

Inconel 600: This material is very popular for high temperature as well as oxidation and used in Inconel 600 Sheets and Plates.

Inconel 625: Offers high strength and fatigue resistance ideal for marine applications.

Inconel 718: Used in aerospace for its ability to withstand extreme temperatures and pressures.

Advantages of Inconel

High-Temperature Strength: Retains mechanical properties at extreme temperatures.

Oxidation Resistance: Ideal for applications involving heat and combustion.

Versatility: Suitable for aerospace, nuclear and marine industries.

What is Stainless Hastelloy?

Hastelloy is one of the nickel-molybdenum-chromium superalloys designed to perform in harsh corrosive environment. It excels in resisting pitting, stress corrosion cracking and oxidation. Hastelloy C-22 Sheets, Hastelloy C-22 Coils and Hastelloy C-22 Plates are commonly used in chemical processing, pollution control and waste treatment due to their exceptional corrosion resistance.

Types of Hastelloy

Hastelloy C-22: Provides excellent resistance to both oxidizing and reducing environments used in Hastelloy C-22 Sheets and Coils.

Hastelloy C-276: Known for its versatility in resisting a wide range of corrosive chemicals.

Hastelloy B-2: Specializes in handling hydrochloric acid and other reducing agents.

Advantages of Hastelloy

Superior Corrosion Resistance: Performs exceptionally well in acidic and chloride-rich environments.

Durability: Long-lasting in harsh chemical processing conditions.

Wide Applicability: Used in pollution control, pharmaceuticals and waste treatment.

Inconel vs Hastelloy: Key Differences

Composition: Inconel is primarily nickel-chromium, while Hastelloy contains nickel, molybdenum, and chromium.

Temperature Resistance: Inconel performs better in high-temperature applications whereas Hastelloy excels in corrosive environments.

Applications: Inconel is used in aerospace and gas turbines while Hastelloy is preferred in chemical and petrochemical industries.

Cost: Hastelloy is generally more expensive due to its superior corrosion resistance.

What to Choose: Inconel or Hastelloy?

Your particular needs will determine which material to choose between Hastelloy and Inconel. Inconel 600 Sheets or Plates are ideal for your application if it involves high temperatures and oxidation. For the environment with extreme corrosion, Hastelloy C-22 Sheets or Coils are the better option.

Conclusion

Inconel and Hastelloy are both excellent materials with specific properties. Hastelloy is good in corrosive environments and Inconel is good in high temperature applications. If you require Inconel 600 Coils or Hastelloy C-22 Plates, it is important to know their differences and advantages to choose the best alloy for your project.